About Us

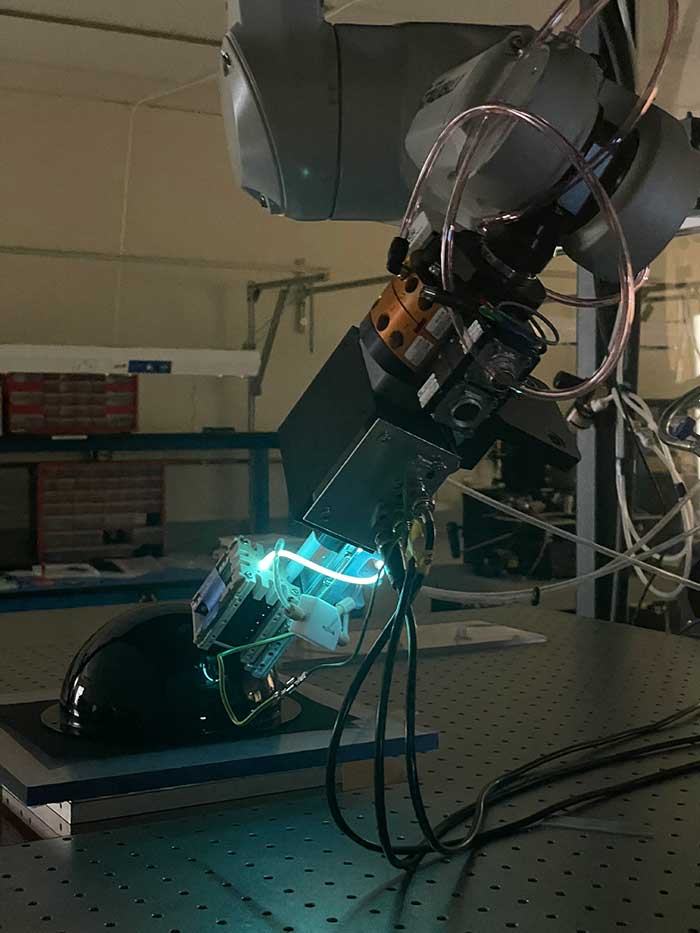

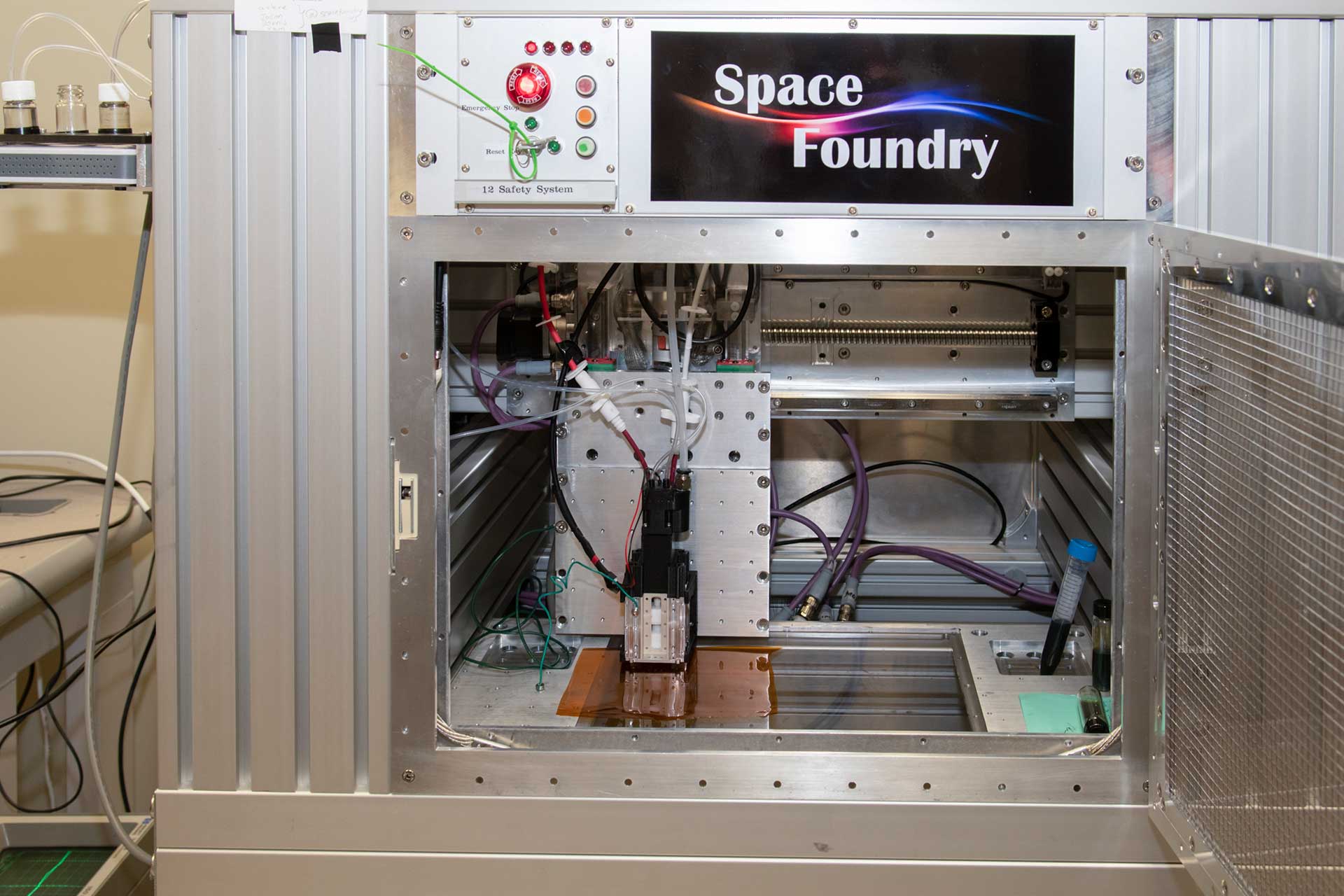

Space Foundry is an equipment manufacturer providing both hardware and printing solutions for printing conductors and dielectrics. Space Foundry’s products include stand-alone R&D printers and also OEM print heads that can be integrated to other additive manufacturing tools and robotic arms.

Dr. Ram Prasad Gandhiraman who was a principal investigator of the plasma processing lab at NASA Ames and Dr. Dennis Nordlund who was a collaborator from SLAC National Accelerator Laboratory are the proud founders of Space Foundry having started the company as they envisioned that the technology could be disruptive.

Prior to the startup formation, the technology was under development at NASA Ames, funded internally by several funding programs of NASA including the NASA Innovative Advanced Concepts (NIAC), Advanced Exploration Systems (AES), Center Innovation Fund (CIF), Directors Discretionary Fund (DDF) and Science Innovation Fund (SIF).

Space Foundry develops and promotes processes for printing conductors and dielectrics. Copper is the primary focus, though a range of metals and metal oxides can be printed. Silicon dioxide dielectric coating can be printed using in-situ plasma polymerization. Our technology also allows tuning the oxidation state and dielectric property of the material being printed using an in-situ process.

Why Space Foundry?

Printed electronics is an evolving electronic devices manufacturing concept that is being adopted by various industry segments including wearables, defense, medical, aerospace and automobile industries. Unlike the traditional electronic devices, the substrates for next generation embedded electronics devices vary drastically in their size, shape, conformity and temperature endurance. The nature of substrates involved in Flexible electronics, in-mold electronics, additive electronics devices are either soft plastics, or have complex large/small geometries and topographies driving the need for innovative manufacturing solutions. The printed electronics industry still needs to mature and evolve towards scalable multi-material printing. Majority of the multi-material additive printing is still in the research and development pending market adoption. One of the critical bottlenecks is the dependency on ink and post processing.

Reliance of the printed electronics industry on ink synthesis and post processing of patterned wet inks limits the market adaption and restricts the progress of the sector.

On the contrary, Plasma Jet Printing is highly scalable and has immense capability to print a wide variety of materials with precisely tailored material characteristics making it the ideal technology for next generation of printed electronics.

Space Foundry’s founders are convinced that the plasma process has the ability to disrupt the ink and equipment industry by being a true enabler and have hence founded Space Foundry to commercialize Plasma Jet Printing Technology.

Space Foundry’s technology has the potential to overcome issues associated with ink and post processing making it a much needed disruptive innovation for the printed electronics industry.